Scientists Create Revolutionary “Superwood” Stronger Than Steel and Completely Fireproof

Wood and the Promise of Reinvention

Wood has always been more than a building material — it’s a symbol of warmth, heritage, and our enduring connection to the natural world. It shapes the walls that shelter us, the furniture that fills our homes, and even the stories we share around a glowing fire. Yet behind its charm lies a set of age-old compromises: wood burns easily, warps in humidity, succumbs to insects, and lacks the brute strength of steel or concrete. For centuries, builders accepted these limitations, turning to heavier, carbon-intensive materials when safety and longevity were at stake.

Now, a new innovation is rewriting that equation. Scientists have developed a next-generation material known as Superwood — a form of engineered timber that is stronger than steel, resistant to fire, water, pests, and decay, yet retains the organic beauty and renewability of natural wood.

Developed by InventWood, a spin-out company from the University of Maryland led by materials scientist Professor Liangbing Hu, Superwood refines ordinary timber at the molecular level. Through a process of chemical treatment and compression, the cellulose fibers within the wood are realigned into an ultra-dense, durable structure. The result is a material that preserves the warmth and grain of natural wood while outperforming conventional building materials in every major category: strength, safety, and sustainability.

This breakthrough goes far beyond construction. It represents a philosophical shift — one where innovation enhances rather than replaces nature. Superwood is a vision of how humanity might harmonize beauty, resilience, and sustainability in the world it builds.

What Is Superwood, Technically

Superwood’s strength does not come from a superficial coating or synthetic reinforcement. Its transformation begins deep within the wood’s internal architecture. The process starts by soaking the timber in a solution of sodium hydroxide and sodium sulfite, which carefully removes part of the lignin and hemicellulose — the natural polymers that give wood its rigidity but also its weaknesses. This step leaves behind a pure network of cellulose nanofibers, the same microscopic threads that make up the backbone of plants.

Next, the treated wood is subjected to intense heat and pressure, collapsing its porous structure and forcing the fibers into perfect alignment. The compression process dramatically increases density, creating a compact, laminated structure with molecular bonds so tight that it behaves more like a metal than a traditional piece of wood.

The outcome is astonishing. Tests show that Superwood’s tensile strength — the amount of stress it can withstand before breaking — is up to 50 percent greater than structural steel of the same cross-sectional area. It also demonstrates exceptional impact resistance and elastic recovery, meaning it can absorb and dissipate energy without fracturing.

Its performance in fire testing is equally impressive. Superwood has achieved a Class A fire rating, the highest possible for construction materials. Flames that would normally consume untreated timber tend to self-extinguish on its surface, a result of the compact structure limiting oxygen penetration. It’s also resistant to water damage, rot, mold, and termites, making it one of the most durable natural materials ever engineered.

Perhaps most excitingly, this process can be applied to a wide variety of wood species — including fast-growing, low-cost varieties like pine, poplar, or bamboo. That means industries can reduce pressure on old-growth hardwood forests while still producing a high-performance material. Superwood could therefore redefine sustainability itself: turning quick-growing trees into ultra-strong materials, aligning ecological health with economic practicality.

Why People Are Excited — and What’s Truly New

The global enthusiasm surrounding Superwood isn’t just about crafting better furniture or stronger beams. It’s about transforming the very foundation of the built environment. Superwood combines strength, safety, and sustainability in a way no other material currently does.

Traditional building materials such as steel and concrete require enormous energy inputs and release vast amounts of carbon dioxide during manufacturing. Superwood, by contrast, begins with a renewable carbon sink — wood — which already stores carbon from the atmosphere. Turning it into a high-performance material without fossil-fuel-intensive processes means a much smaller carbon footprint for construction, an industry responsible for nearly 40 percent of global emissions.

Beyond sustainability, Superwood’s versatility is changing design possibilities. Because it can be produced from inexpensive, fast-growing species, it democratizes access to premium-quality materials. Imagine entire skyscrapers or modular homes built from eco-friendly wood that’s as strong as steel yet as beautiful as walnut or oak.

Architects, designers, and builders are captivated by this dual promise — high performance and aesthetic warmth. The ability to construct durable, fireproof, and sustainable structures without sacrificing the natural appeal of wood opens creative freedom that traditional materials cannot match.

Symbolically, Superwood also redefines what innovation means. It’s not a rejection of nature but a refinement of it. Just as steel revolutionized 19th-century architecture, engineered wood of this caliber could mark the next great leap in sustainable design — the defining material of the 21st century.

Practical Examples and Potential Uses

Although still emerging, Superwood’s potential applications span across industries. In construction, it’s already being tested for cladding, façades, and load-bearing elements. External panels face some of the toughest environmental conditions — UV radiation, rain, wind, and fire. Superwood’s ability to withstand these challenges while maintaining its visual appeal makes it an ideal choice for next-generation building envelopes.

In furniture and interior design, its strength and resilience mean longer-lasting products with minimal maintenance. Imagine flooring that resists dents and moisture, or cabinetry that retains its finish for decades. A dining table made of Superwood could retain the warmth of oak yet shrug off stains, scratches, and even heat.

Looking ahead, researchers envision using Superwood in beams, structural frames, bridges, and even prefabricated homes. As building codes evolve to accommodate the material, cities of the future could rise from engineered wood instead of cold concrete — reducing emissions and humanizing urban landscapes.

Its possibilities extend well beyond architecture. Because it is lightweight yet strong, Superwood has potential in transportation, from automotive interiors to railcar components and aircraft cabins, where reducing weight improves energy efficiency. Even the packaging industry, currently dominated by plastics, could benefit from a biodegradable alternative that’s both durable and recyclable. These additional markets could accelerate mass adoption, bringing costs down and expanding Superwood’s global footprint.

What’s Not Yet Solved

Despite its promise, Superwood faces real challenges. Cost remains a key barrier: the combination of chemical treatment and high-pressure densification is more expensive than standard timber processing. Until manufacturing scales up, it may remain a premium material reserved for flagship projects.

There are also engineering considerations. While Superwood’s tensile strength is impressive, its stiffness — or resistance to bending — doesn’t always equal that of steel. This limits its immediate use in long-span bridges or skyscrapers without additional reinforcement. Researchers are exploring hybrid designs that combine Superwood with metals or carbon fiber to address this issue.

Environmental management is another concern. Although the chemicals used are less harmful than those in industrial steelmaking, they still require energy and careful disposal. Long-term data on weathering, UV exposure, and biodegradation are still being gathered. Building regulations, which are intentionally conservative, will need years of field testing before fully certifying the material for large-scale use.

And then there’s the human factor. The construction industry is often slow to adopt new materials, bound by tradition, regulation, and risk aversion. For Superwood to become mainstream, its advocates will need to pair data with education and storytelling — helping builders, regulators, and the public see it not as a novelty, but as the logical next step in sustainable design.

Why This Matters for How We Build and Live

Superwood represents more than just a materials breakthrough — it’s a statement about the future of human progress. It shows that innovation doesn’t always require abandoning the old, but rather improving upon it. Wood has been humanity’s oldest building companion, from ancient huts to soaring cathedrals. By refining it instead of replacing it, we align technology with ecology in a way that feels both futuristic and deeply familiar.

In a world grappling with climate change, Superwood offers a tangible path forward — a material that embodies resilience, circularity, and renewal. If mass production becomes feasible, it could enable affordable, disaster-resistant housing in regions where termites, humidity, and fire currently make wooden construction impractical. Entire communities could gain safer homes built from sustainable resources rather than imported steel or cement.

Beyond its technical value, Superwood carries a powerful metaphor: when fibers align under pressure, they become stronger together. The same could be said for societies confronting environmental and social challenges. Innovation like this reminds us that collective alignment — human creativity working in harmony with nature — can yield solutions stronger than anything we’ve known before.

And perhaps that’s Superwood’s greatest gift. It’s a triumph born from curiosity — from asking a simple question: How can we make wood better? From that question emerged a vision of the future where sustainability and strength no longer stand in opposition, but grow from the same root.

News in the same category

The Hidden Meaning Behind Tongue Piercings Most People Don’t Know

The Wondiwoi Tree Kangaroo Returns After Nearly a Century of Silence

Why do many men love married women more than single women?

5+ Things That Men Actually Notice About Women

This Is the Most Attractive Hobby a Man Can Have, According to Women

Pick The Underwear You Would Wear To Reveal What Kind Of Woman You Are

What to Do If Your Child Is Bitten by a Strange Bug

If you're caught Googling these four words Police may show up at your house

Fascinating animation reveals exactly how gas pumps know when to stop pouring gas

Elon Musk's Starlink satellites could be falling out of the sky

Expert issues chilling warning on Elon Musk's robots as billionaire plans to put them on Mars

Jeff Bezos sent a secret tourist into space and their identity is set to be revealed

Super typhoon set to send shockwaves through the US is just days away

Moon Meets Mars: A Dazzling Celestial Encounter on October 11, 2025

All DNA and RNA Bases Found in Meteorites: Life’s Origins May Be Cosmic

Did You Know? A Spider in Your Home Could Be a Powerful Sign

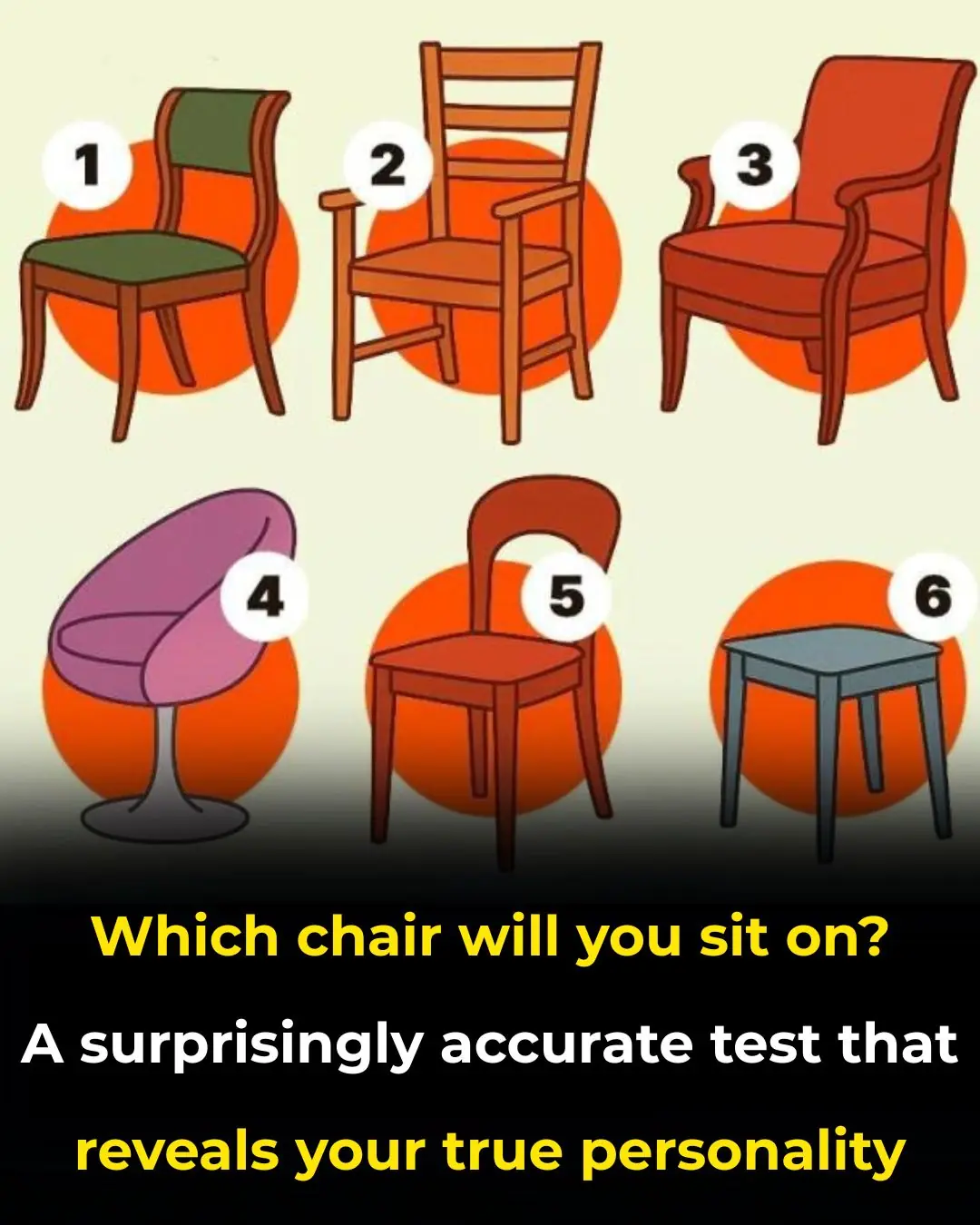

Which Chair Would You Choose

Why some men cheat but choose to stay in their marriage — the truth few understand

News Post

Garlic, tomatoes and cucumbers will grow rapidly. The most powerful fertilizer.

12 Powerful Benefits of Moringa Seeds

25 Incredible Health Benefits of Goosegrass

Pineappleweed (Matricaria discoidea) – Nature’s Calming Herb with Surprising Benefits

Grow potatoes in containers at home with just one potato

A Heartwarming Story of Hope: Surrendered Dog in Christmas Sweater Awaits a Loving Home

The Power of Chanca Piedra: 10 Benefits and Uses

Wood Sorrel Benefits and Uses

Forever Our Indy: A Tribute to a True Best Friend

The four medicinal leaves: Avocado leaves, mango leaves, bay leaves, and guava leaves

People Spotted a Dog Collapsed on a Sidewalk — Then Realized She Was Still Alive

This Senior Dog Can’t Climb the Stairs Anymore — So Dad Sleeps on the Sofa with Him Every Night

A Final Goodbye: Mario’s Last Moment with the Giraffes He Loved

Shy Golden Retriever Saved From Euthanasia at the Last Moment

The Dog Who Beat Cancer: A Reunion That Moved the World.

The Lion Who Lost His Mane, and the Tiger Who Won His Heart.

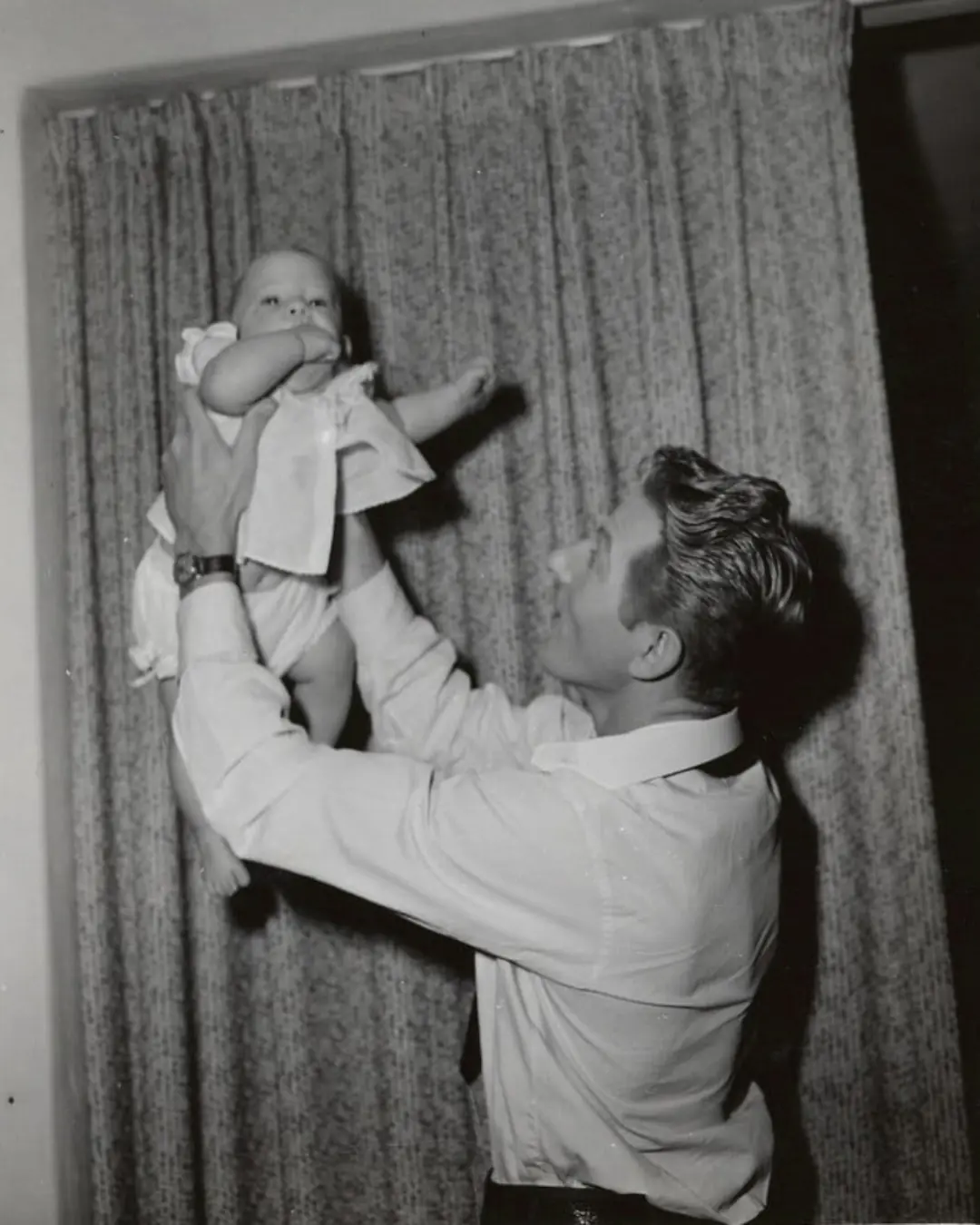

Her Heart Belongs to Daddy: A Daughter’s Memory of Danny Kaye.

A Father Chosen by Love

Goodbye, Noor Jehan: The Elephant Who Made a Nation Weep.