China Successfully Tests 3D-Printed Micro Turbojet Engine in Landmark Flight Achievement

China has marked an important advance in aerospace engineering with the successful test flight of a 3D-printed micro turbojet engine, signaling a growing maturity in the use of additive manufacturing for real-world aviation applications. The engine was developed by the Aero Engine Corporation of China (AECC), a state-owned enterprise at the center of China’s aircraft propulsion research and production. Unlike many experimental projects that remain confined to laboratories, this engine is a fully functional model that has now been validated under actual flight conditions.

The test flight was conducted in the Inner Mongolia Autonomous Region, where the engine demonstrated stable and reliable performance. During the trial, it reached an altitude of approximately 4,000 meters and generated 160 kilograms of thrust, confirming that the design can meet practical operational requirements. These results represent a notable step forward, as small turbojet engines are often used as testbeds for new technologies before they are scaled up for larger aircraft or specialized platforms such as drones and unmanned aerial vehicles.

A central innovation behind this achievement lies in the engine’s design methodology, described by AECC as “multidisciplinary topological optimization.” This advanced engineering approach integrates aerodynamics, structural mechanics, thermodynamics, and materials science into a single design framework. By optimizing multiple variables at once, engineers were able to significantly reduce the engine’s weight while maintaining the strength and durability required to withstand high temperatures and rotational stresses. Traditional manufacturing techniques frequently struggle to achieve this balance, as they are constrained by tooling limits and simpler internal geometries.

The use of 3D printing, or additive manufacturing, played a critical role in turning these optimized designs into physical components. Additive manufacturing allows engineers to produce intricate internal channels and lattice structures that are either impossible or prohibitively expensive to create using conventional casting or machining. In this case, such complex internal features contributed to improved airflow, better thermal management, and overall gains in efficiency and performance. Although AECC has not disclosed detailed information about the specific materials or printing processes employed—likely for commercial and security reasons—the successful flight test itself demonstrates that these components can endure real operational stresses.

Experts note that this milestone reflects broader global trends in aerospace manufacturing. International research organizations and industry leaders, including NASA, GE Aerospace, and Rolls-Royce, have increasingly emphasized additive manufacturing as a way to shorten development cycles, reduce costs, and enable innovative designs. Academic journals such as Nature and Additive Manufacturing have also highlighted the growing readiness of 3D-printed metal components for high-performance aerospace use.

In this context, AECC’s successful test flight underscores China’s accelerating capabilities in advanced propulsion technology. Beyond its immediate technical significance, the achievement opens new possibilities for the future of aircraft engine design and production, particularly for lightweight engines, rapid prototyping, and customized solutions. As additive manufacturing continues to mature, such developments may reshape how next-generation aircraft engines are conceived, built, and deployed.

Sources (newly added):

-

Aero Engine Corporation of China (AECC) official releases

-

Xinhua News Agency

-

Aviation Week & Space Technology

-

Nature and Additive Manufacturing journals

-

NASA and GE Aerospace publications on additive manufacturing in aviation

News in the same category

Study Finds a Mother’s Early Bond With Her Baby Can Shape a Child’s Sleep for Years

Gramma the Tortoise: A Remarkable Life Spanning Three Centuries

California Surpasses Japan to Become the Fourth-Largest Economy in the World

Why Aging Skin Develops a Distinct Body Odor—and What Science Says Can Help

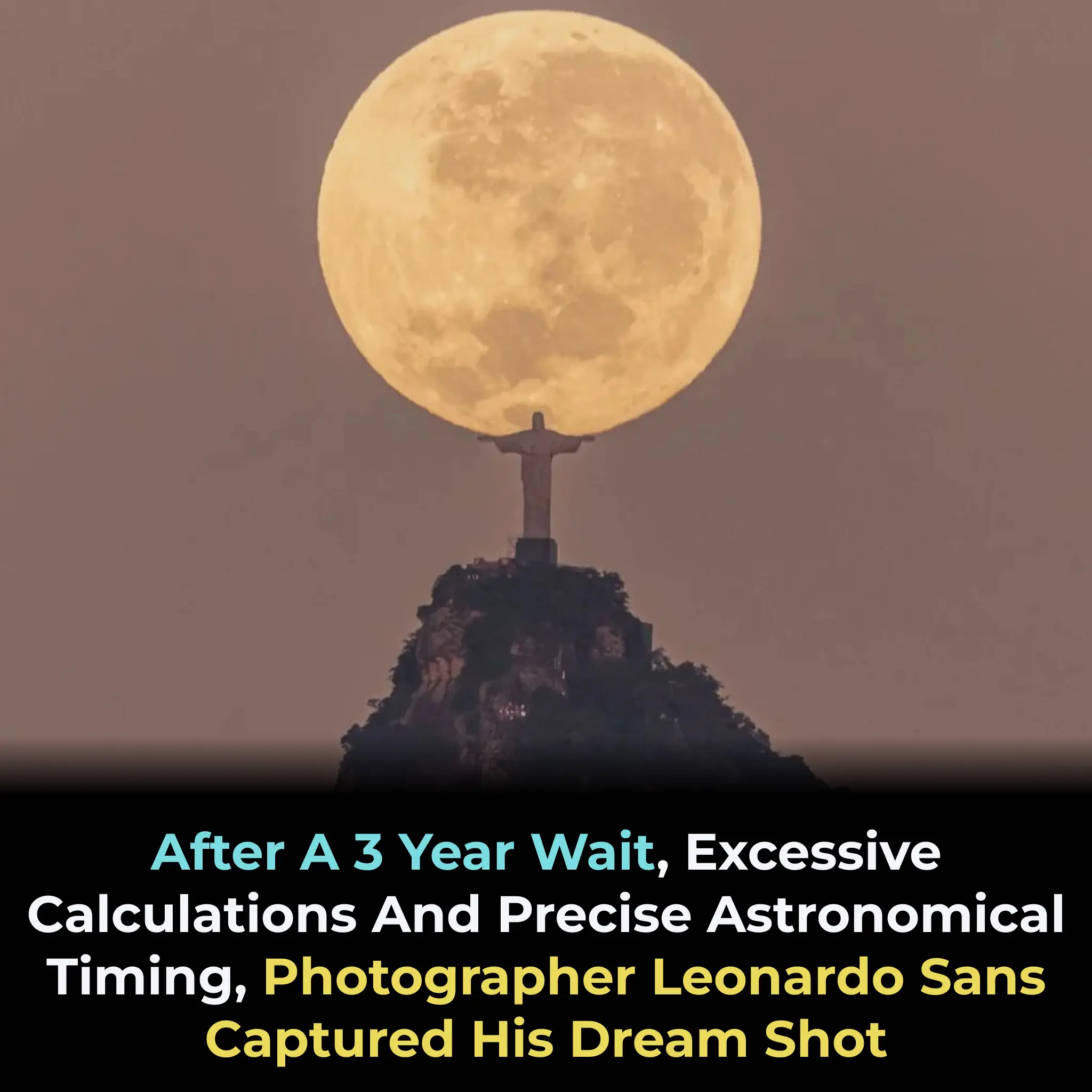

Photographer Captures Dream Shot of Full Moon Over Christ the Redeemer After Three Years of Effort

Swiss Researchers Trial Blood Filtration Device for Alzheimer's Treatment

Bear Takes Over Truckee Diner in Hilarious Culinary Heist

Many people believe they need to walk ten thousand steps daily to stay healthy

The Quieting Skies: A Stark Decline in North America's Bird Population

Sea Otter Takes Over Santa Cruz Surf Scene: A Bold and Unpredictable Presence

Australia's Revolutionary Bionic Eye: A New Era in Restoring Vision

What does it symbolize when a person who passed away appears in your dream

Tiny Pumpkin Toadlet Discovered in Brazil's Atlantic Forest: A New Species of Vibrantly Colored Frog

Overview Energy's Bold Plan to Beam Power from Space to Earth Using Infrared Lasers

Japan’s Ghost Homes Crisis: 9 Million Vacant Houses Amid a Shrinking Population

Japan’s Traditional Tree-Saving Method: The Beautiful and Thoughtful Practice of Nemawashi

Swedish Billionaire Buys Logging Company to Save Amazon Rainforest

The Farmer Who Cut Off His Own Finger After a Snake Bite: A Tale of Panic and Misinformation

News Post

How to Make a Simple DIY Water Filter in an Emergency

Mullein: The Wild Plant That Clears Your Lungs Naturally

The Hidden Power of Xanthium strumarium (Cocklebur)

25 Remarkable Benefits of Guava Leaves and How to Use Them Safely

Study Finds This Popular Sweetener Damages the Brain’s Protective Barrier

Study Finds a Mother’s Early Bond With Her Baby Can Shape a Child’s Sleep for Years

Gramma the Tortoise: A Remarkable Life Spanning Three Centuries

California Surpasses Japan to Become the Fourth-Largest Economy in the World

Why Aging Skin Develops a Distinct Body Odor—and What Science Says Can Help

Photographer Captures Dream Shot of Full Moon Over Christ the Redeemer After Three Years of Effort

Swiss Researchers Trial Blood Filtration Device for Alzheimer's Treatment

Bear Takes Over Truckee Diner in Hilarious Culinary Heist

Many people believe they need to walk ten thousand steps daily to stay healthy

The Quieting Skies: A Stark Decline in North America's Bird Population

Does This Drink Really Harm Your Bones? The Truth Behind Soda and Your Health

Oregano: The Small Plant with Big Health Benefits

Sea Otter Takes Over Santa Cruz Surf Scene: A Bold and Unpredictable Presence

Australia's Revolutionary Bionic Eye: A New Era in Restoring Vision