Why Do Flat Electrical Plugs Have Two Round Holes? The Hidden Purpose Is Brilliant

Have you ever noticed the two tiny round holes near the tips of a flat electrical plug’s metal prongs and wondered what they’re for?

Most of us use plugs every day without giving them a second thought. But in fact, every detail in a plug’s design — even those little holes — has been carefully engineered for function, safety, and efficiency.

🔌 The Main Purpose: A More Secure Connection

The first and most important function of the two small holes is to help lock the plug securely into the socket.

Inside most standard electrical outlets, there are small bumps or spring catches designed to fit snugly into those holes. When the prongs are inserted, these catches hold them tightly in place, preventing the plug from slipping out accidentally. This ensures a steady electrical connection and reduces the risk of loose contact, which can cause sparks or overheating.

So next time your plug clicks perfectly into place, those tiny holes are partly to thank!

🧒 Added Safety — Especially for Children

Another purpose of the holes is safety. Some socket designs include built-in shutters or safety locks that align with these holes, preventing accidental contact with the live parts.

This is particularly important in households with children — plugs without holes can become loose over time, leaving a small portion of the metal prong exposed. That increases the risk of electric shock. The hole-based locking mechanism helps minimize this danger, keeping both adults and children safer.

🔥 Reduced Friction and Safer Plugging

In older plug designs, the prongs had indented grooves instead of holes. These grooves increased friction when plugging and unplugging, sometimes causing small sparks (electrical arcing).

By switching to rounded holes, manufacturers were able to reduce friction and make the plugging process smoother and safer. It also lowered the risk of arcing and damage to both the plug and socket.

🏷️ Manufacturing and Quality Benefits

Modern manufacturers have found additional uses for these holes:

-

They can attach security seals or authenticity tags, helping consumers distinguish genuine products from counterfeits.

-

During production, the holes allow the plug prongs to be held more securely by assembly machines, improving efficiency.

-

The small holes also save a tiny amount of metal with every plug — insignificant on one unit, but meaningful when producing millions of pieces. Over time, this contributes to lower material costs and more sustainable manufacturing.

💡 Who Invented This Design?

The idea of adding holes to plug prongs was developed by Harvey Hubbell Jr., an American inventor and electrical engineer.

In his early designs, Hubbell added small notches and indentations to improve contact inside the socket. Later, he replaced them with full holes for better locking and safety — a concept so effective that it’s still used in modern plugs today, over a century later.

🌍 Plug Types That Use the Hole Design

Today, you’ll mostly find this feature on Type A and Type B plugs:

-

Type A: Two flat parallel blades (common in the U.S., Japan, and Canada).

-

Type B: Two flat blades plus one round grounding pin for protection against electric shock.

Both types follow the NEMA standard (National Electrical Manufacturers Association) — the American benchmark for plug and socket design.

In contrast, many countries in Europe and parts of Asia use round-pin plugs (Type C, E, or F), which fit tightly into matching round sockets. These designs don’t need holes because the circular connection itself ensures stability.

⚙️ In Summary

Those two tiny holes on your flat plug aren’t random decorations — they’re the result of smart engineering and over a century of design evolution.

They help:

-

Lock the plug firmly in place

-

Improve safety for users (especially children)

-

Reduce wear and electrical arcing

-

Simplify manufacturing and quality control

So the next time you plug in your phone charger or laptop adapter, take a closer look — those little round holes are a reminder that even the smallest design details can make a big difference in safety, efficiency, and innovation.

News in the same category

Bad Habits After Doing Laundry That Can Make Your Whole Family Sick! Many People Overlook This Detail

Don’t Throw Away Your Used Balm Jar – Here’s a Super Useful Way to Reuse It That Every Family Needs

A Small Button on Your Refrigerator Can Save You Millions on Electricity: Many People Don’t Know This

The Little Aluminum Ring on a Sausage Stick Has a Hidden Use — Few People Know Its Clever Purpose

Don’t Eat Tofu Right After Buying It — Freeze It First for a Magical Effect: You’ll Wish You Knew This Sooner

Pour This Liquid Into the Drain – The Unpleasant Odor in Your Bathroom Will Quickly Disappear

Get Rid of Termites in Wooden Doors Easily – Keep Your Wood Beautiful for 10 Years

What you see reveals your personality

You’re doing it all wrong. Here’s the right way to store knives

You’re doing it all wrong. Here’s the right way to unclog your drain

10 cooking cleanup habits you’re doing wrong

Genius!

Need some assistance here

Tips for choosing clean, natural vegetables without worrying about harmful chemicals

3 benefits of putting lemon sprinkled with salt in the room, the last one many women like

Experience in growing tomatoes in pots with lots of fruit, plant one plant and eat all year round, no need to buy

After boiling the chicken, do this step: The chicken will have golden brown, crispy skin, and will be delicious to eat.

Want to eat ripe jackfruit, don't 'absorb' chemicals, go to the market and choose this way

News Post

Vertical Nail Ridges? Here’s What Causes Them — and How to Fix It

The Unseen Heroes: A Rescue Dog's Loyalty That Saved My Life

Barrett’s Miracle: A Journey of Faith, Strength, and Prayer

A Farewell to a Friend and His Passion for Music

Top 5 Nutrients to Reduce Swelling in Feet and Legs

A Rare Encounter: The Moment a Mountain Lion Meets a Baby

Stray Cats Bring a Bitcoin Mine to a Standstill — And Melt Hearts in the Process

If you sleep with socks on, see what happens

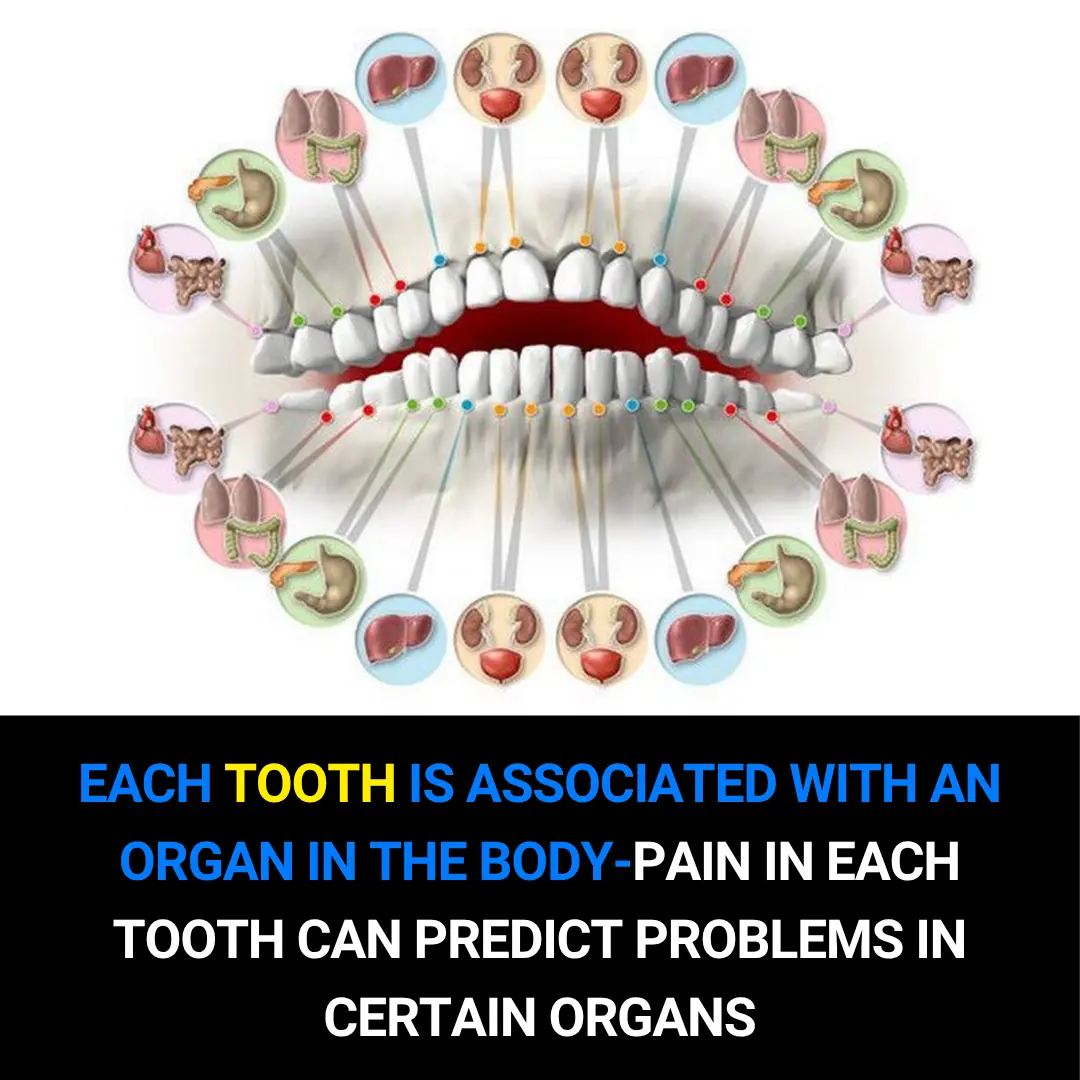

Each Tooth Is Connected to an Organ in the Body – How Tooth Pain May Reveal Hidden Health Problems

Dominika’s Fight for a Childhood Without Pain

Why There's A Growing Trend Of Straight Men Dating Trans Women

Michalinka’s Fight for Life: A Tiny Body, a Giant Spirit

A Miracle in the Making: Baby Harlan’s Fight for Life

From Tragedy to Triumph: The Unbreakable Spirit of Janey Carter

A Battle of the Wild: The Confrontation Between a Raging Elephant and a Baby Hippo

7 Heart-Healing Foods Your Cardiologist Won’t Tell You About

Never Clean Your Light Switch with Water: Here’s a Trick to Make It Spotless

Bad Habits After Doing Laundry That Can Make Your Whole Family Sick! Many People Overlook This Detail

Don’t Throw Away Your Used Balm Jar – Here’s a Super Useful Way to Reuse It That Every Family Needs