There are two round holes on the plug, and their magical use is little known.

The Hidden Purpose of the Two Small Holes on Electrical Plugs

Have you ever noticed the two small round holes on the metal prongs of many electrical plugs? Though they seem trivial, their purpose is surprisingly important, yet often unknown. These small features actually play a crucial role in the safety, functionality, and manufacturing of electrical plugs. Here’s why these holes are more important than you might think.

1. They Help the Plug Lock Securely into the Outlet

One of the most important functions of these small holes is to help the plug lock securely into the outlet. Inside many wall outlets, there are small bumps or spring-loaded catches that interact with these holes when the plug is inserted. These catches engage with the holes, creating a tighter and more stable connection.

The result is a plug that stays in place more securely, preventing it from slipping out of the outlet easily. This locking mechanism helps ensure that the electrical connection is stable, which not only prevents the plug from being pulled out accidentally but also reduces the risk of sparks or loose connections. This is particularly vital in preventing short circuits, which can lead to electrical fires.

2. They Improve Safety by Preventing Accidental Disconnection

Another key benefit of these holes is that they prevent accidental disconnection. When the plug is securely locked in place, it stays attached to the outlet even if the cord is slightly pulled or moved. This reduces the chances of partial contact, which could otherwise generate heat or cause electrical arcing, both of which are dangerous.

In environments where electrical plugs are frequently moved or pulled, such as workshops or homes with active appliances, this feature significantly reduces the risk of a malfunction. It also improves safety by ensuring that the plug remains firmly in place, preventing damage to both the plug and the outlet over time.

3. They Make Manufacturing Safer and Simpler

These small holes also contribute to the manufacturing process by making it simpler and safer. During the production of electrical plugs, machines use the holes to hold the metal prongs securely in place while the plastic plug body is molded around them. Without these holes, the prongs could shift or slide out of position during the assembly process, leading to misalignment and potential defects in the final product.

By providing a reliable method for holding the prongs steady, these holes help streamline the production process and ensure the consistency and quality of the plugs being made. This reduces the chances of faulty plugs reaching consumers and contributes to higher safety standards for the end product.

4. They Allow Compatibility with Certain Locking Devices

In certain industrial or workplace settings, additional safety measures are often required. Some work environments use special locking devices to prevent plugs from being removed unintentionally, such as in factories or areas with heavy machinery. These two small holes allow locking clips or other safety accessories to be attached to the plug, making it impossible to unplug the device without the proper key or tool.

This added layer of security helps protect critical machinery or devices from being accidentally unplugged, which could lead to equipment downtime, safety hazards, or even damage to expensive tools. It also adds a level of security that can be especially important in areas where unauthorized access is a concern.

5. They Help Reduce Material Use

Although they are small, the holes in the prongs of electrical plugs also have an environmental benefit. By reducing the amount of metal needed to produce each prong, these holes help save on material costs. When producing millions of plugs, these savings can add up significantly, reducing both production costs and material waste.

This subtle reduction in material use also contributes to a more sustainable manufacturing process, which can be important for companies aiming to reduce their environmental impact. While the holes themselves are small, they serve a larger purpose in streamlining production without compromising the quality or performance of the plug.

In Summary:

While the two small holes on a plug may seem like a minor detail, they actually serve several important purposes that contribute to both the safety and efficiency of electrical connections. Here's a quick recap of their functions:

-

Secure connection: The holes help lock the plug firmly into the outlet, preventing it from falling out due to vibration or pulling.

-

Safety: They improve safety by preventing electrical arcing and shock risks caused by loose connections.

-

Manufacturing efficiency: These holes make the manufacturing process safer and simpler by holding prongs in place during assembly.

-

Compatibility with locks: In industrial or workplace settings, these holes allow plugs to be locked in place, preventing unauthorized disconnections.

-

Material savings: The holes help reduce the amount of metal needed in production, contributing to cost and material savings.

While it may seem like a surprising feature, these two small holes are a practical and effective solution that ensures a better and safer electrical connection. They help prevent accidents, improve the efficiency of plug manufacturing, and reduce environmental impact—all without any "magic" involved. This simple design is a great example of how small details can have a big impact on both safety and functionality.

News in the same category

How to get rid of urinary tract infections completely naturally according to science

Without a drop of chemicals, the whole vegetable garden suddenly grew big, thanks to this simple thing.

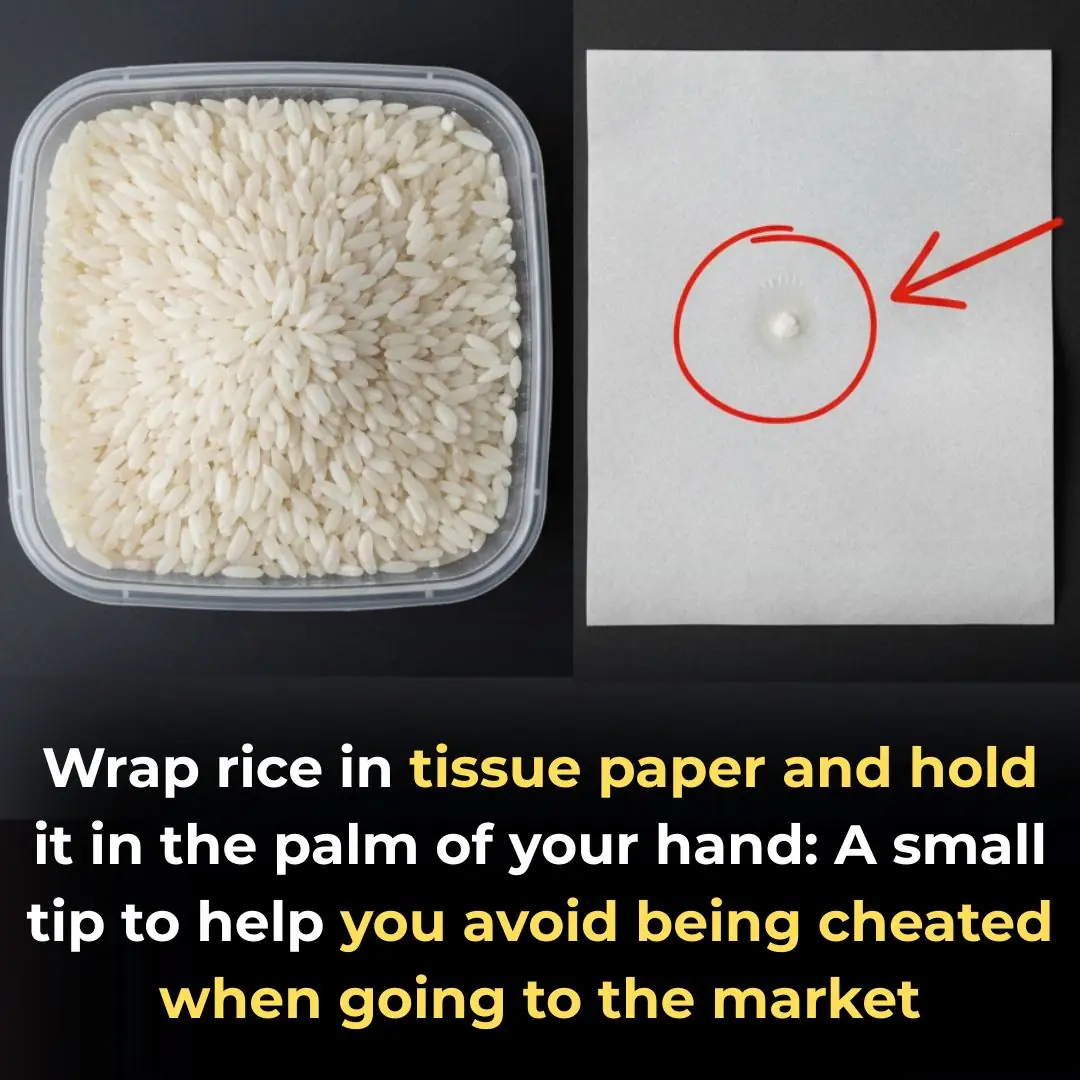

Wrap rice in tissue paper and hold it in the palm of your hand: A small tip to help you avoid being cheated when going to the market

Tips for conditioning hair with black vinegar, both economical and helps reduce hair loss and grow faster

There is a small part on the shrimp: Just look at it and you can easily tell if it is farmed shrimp or wild shrimp.

Show you 4 effective ways to keep your house free of cockroaches

Bean sprouts should be soaked in this water to remove toxic substances.

This type of powder is commonly found in the kitchen. Just sprinkle a little on bonsai plants and they will sprout buds and bloom all over the garden.

Stir-fried vermicelli without it sticking or clumping together with this simple secret: Simple but I didn't know it for so long

How to Make Your Stainless Steel Pots Shine Like New and Choose Sweet, Juicy Oranges

Just tried this and whoa

Beer on the Window Sill: A Simple Trick With Surprising “Magic” Benefits

You are doing it all wrong. Here's the right time to eat tomatoes

Try This Method: Clean Your Floors Just Once a Week—They Stay Shiny, Fresh, and Dust-Free

10 Foods That Help Beat Fatty Liver: Nutrition Experts Recommend Eating Them Daily

5 types of fish “loaded” with mercury – don’t be tempted even if they are cheap

6 Surprising Ways to Use Dishwasher Pods Around the House

Keep chilies fresh for months with this simple method — they’ll stay as vibrant and crisp as the day you picked them

News Post

A Forgotten Car’s Journey: Rediscovered, Remembered, and Recycled

Revolutionary Gel from Germany Offers Non-Surgical Solution for Cartilage Regeneration

From Playground to Graduation: The Enduring Power of Childhood Friendship

The Spruce Pets – Creative ways to feature cats and dogs in weddings.

The Water Man of Tsavo: A Hero's Mission to Save Wildlife from Drought

Better Sleep, Healthier Spine: Why You Should Avoid Stomach Sleeping

Plumbing Mayhem on Brown Friday: How Holiday Feasts Overload Pipes

Don’t Pour Hot Water Into a Clogged Sink — Do This Instead for a Quick Fix and Fresh Smell

Rare Orange Shark With Ghostly White Eyes Captured in First-of-Its-Kind Sighting

Health Alert: Contaminated DermaRite Products Recalled Across U.S. and Puerto Rico

Panic Attacks And Anxiety Linked To Low Vitamin B6 And Iron levels

The Science of Rare Steak Versus Rare Chicken

Into the Darkness: A Bioluminescent Jellyfish Illuminates the Deep Ocean

Scientists Discovered How to Kill Prostate Cancer Cells Without Harming Healthy Tissue — Here’s the Breakthrough

The effortless daily trick people use to double their potassium

Germany’s 95% Renewable Power Day: Progress, Challenges, and Lessons for the Future

The Rower Who Chose Humanity: How Bobby Pearce Made History in Amsterdam 1928

Government Set to Phase Out Animal Testing and Replace It With Controversial Alternative